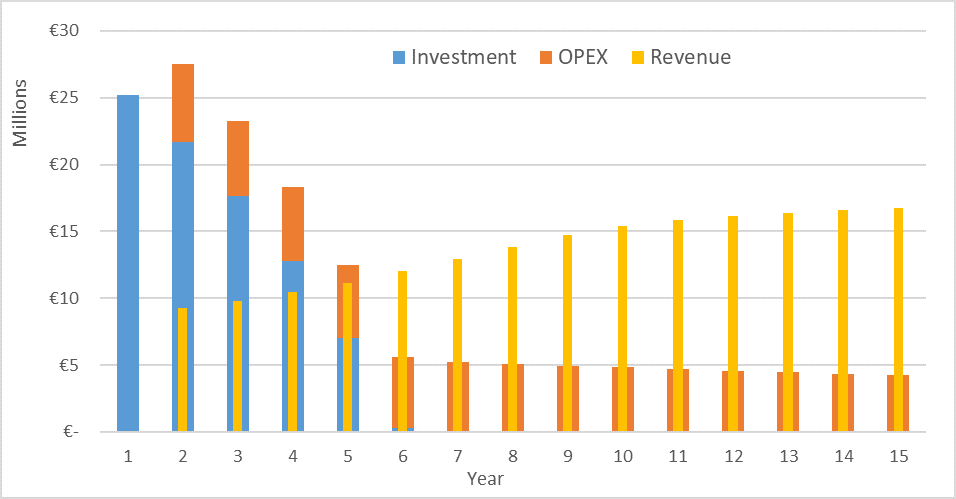

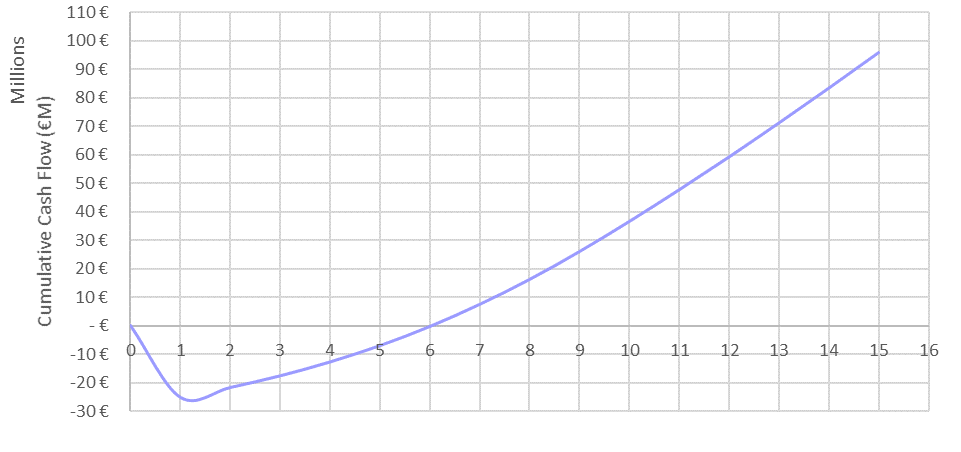

The PLATIRUS project has successfully achieved its goal of developing a business plans based on the novel PLATIRUS Flowsheet for the recovery of PGM from secondary resources such as spent automotive catalysts. The economic assessment of the PLATIRUS Flowsheet shows that making a profitable business with the produced PGM is feasible, even with conservative scenarios (see cash flow evolution in Figure 1).

These scenarios contemplate a PLATIRUS plant able to handle an input of 100t of spent automotive catalysts annually from which 335kg of high purity PGM could be produced. Initial low yield has been considered in these conservative scenarios since they are inherent to the low TRL and scale of operation at the early years when ramping up and optimization of the production is necessary.

Starting from low PGM recovery rate in the first year of production as low as 32% and improving the recovery rate to only 75% after 15 years, a total average production cost of €12.600 per kg of PGM could be achieved. This would result in a payback period of 6 years (see Figure 2) and an accumulated revenue of almost 4 times the initial investment that would be reached in the fifteenth year of production.

Both these two figures clearly demonstrate the highly competitive market potential of the PLATIRUS Flowsheet, being well placed to be scaled up to a higher scale with automotive catalysts as feedstock.